How Long Do Steel Internal Doors Last?

A Complete Longevity Guide for Modern Homes

Introduction

How long does a steel internal door actually last?

If you search online, you’ll quickly find conflicting information, most of it incorrect.

That’s because nearly all online discussions refer to exterior metal or security doors: the hollow, foam-filled, thin-skinned doors used for outbuildings, fire escapes or commercial units. They have nothing in common with welded steel-glazed internal doors crafted for contemporary homes.

Architectural steel doors behave differently. They perform differently, they age differently and their longevity is entirely different.

This guide breaks down every factor that influences lifespan so homeowners, architects, interior designers and contractors can make informed decisions with complete clarity.

Why Most Online Lifespan Advice Is Wrong

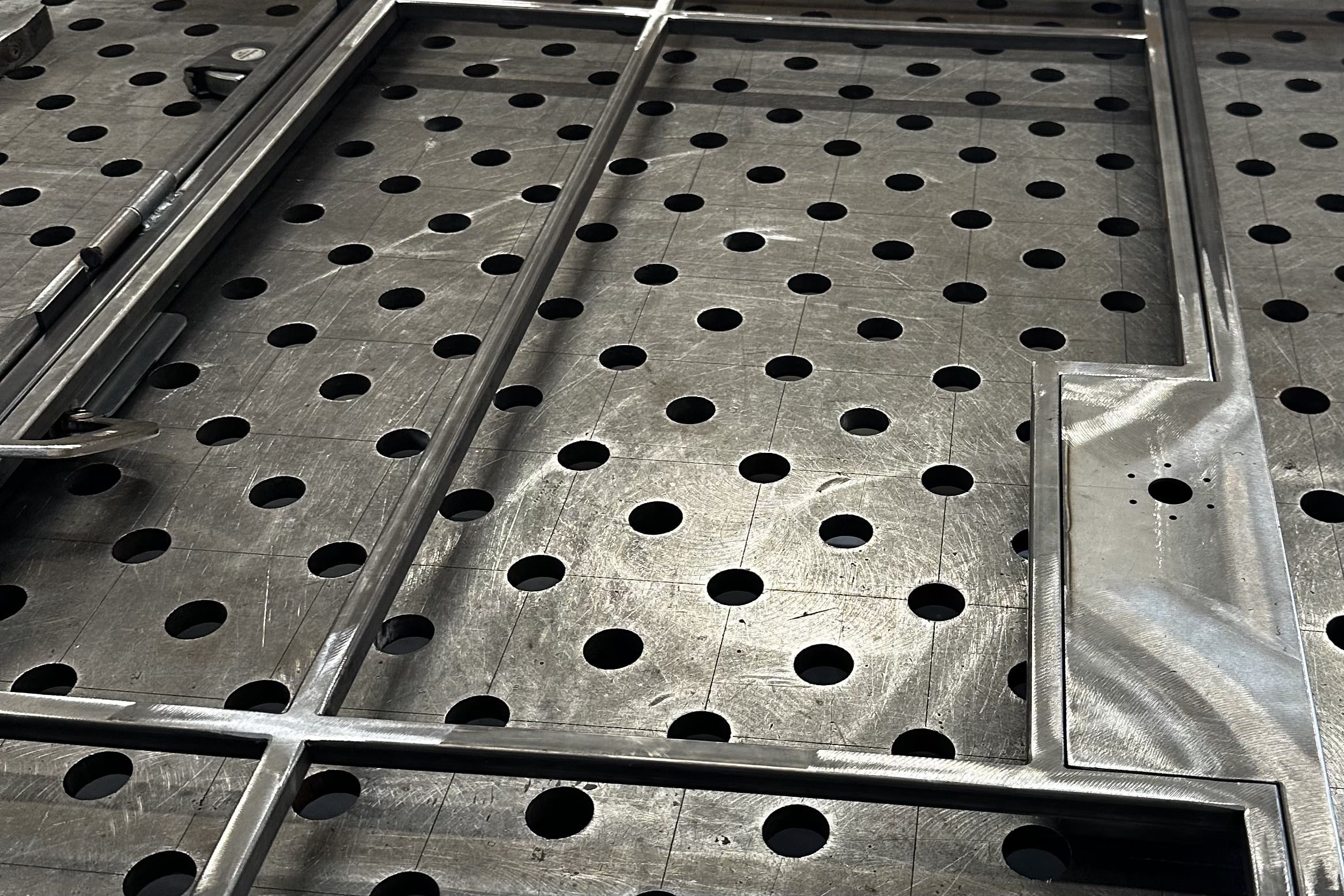

ALT Text: “Comparison between internal welded steel doors and external metal security doors showing different lifespans.”

Image Description: A graphic or side-by-side photo showing the structural difference between a welded steel internal frame and a thin external metal door.

When you search “How long do steel doors last?”, the results overwhelmingly focus on:

denting

rust

weather exposure

insulation

burglary resistance

corrosion

thermal bridging

None of this information applies to internal steel-glazed doors.

External metal doors often last 10–15 years, while internal welded steel doors often last 50+ years.

The two shouldn’t even share the same category.

The True Lifespan: 50+ Years With Minimal Maintenance

The real answer: A correctly made internal steel door can last longer than almost any other component in a home.

The frame itself can easily last a lifetime, or even multiple generations, because:

Steel does not warp.

Steel does not swell with humidity.

Steel does not flex under normal use.

Welded frames become a single unified structure.

Powder coating protects steel for decades.

Glass never bows, twists or deteriorates indoors.

Most homeowners will never need to replace a correctly fabricated steel internal door.

This places steel far above aluminium and timber when evaluating longevity.

What Makes Steel Naturally Long-Lasting?

Material Strength

Steel has one of the highest strength-to-size ratios of any architectural material. This means slim frames can support large glazed panels without bending or fatigue.

Dimensional Stability

Steel remains straight. It does not react to humidity or temperature in the way timber does.

Inert Indoors

Internal environments protect steel from UV, weather, moisture cycling and thermal expansion. This dramatically extends its lifespan.

Impact Resistance

Steel’s hardness means it withstands physical use far better than aluminium (which dents) or timber (which chips).

The material itself is already optimised for longevity but fabrication is what unlocks its full potential.

Welded Construction: The Lifespan Multiplier

Why welding matters

A welded steel frame is one continuous structure. Every joint becomes part of the frame, making it solid, immovable and extremely stable.

The benefits of welding for lifespan:

Zero joint movement over time

No screws to loosen

No mechanical pressure clips

No brackets that fatigue

No cracking at connections

Perfect alignment for decades

Handles and hinges remain stable

Bars stay perfectly in line

Aluminium “steel-look” systems rely on screws, clips and mechanical joints.

They loosen.

They shift.

They flex.

This is the biggest cause of premature failure and it’s why welded steel lasts many times longer.

Precision Fabrication & Quality Control

Longevity begins long before installation.

Key fabrication factors that extend lifespan:

Correct steel grade selection

Precision cutting to eliminate stress

Clean, strong welds

Grinding and refining for smoothness

Checking alignment at each stage

Pre-finishing inspection

Proper powder coat bonding

Correct glazing preparation

Testing door movement before coating

Your process is extremely rigorous, which directly affects long-term performance.

Powder Coating: The First Protective Layer

Powder coating isn’t just aesthetic; it is a protective shell.

Why powder coating extends lifespan:

Extremely resistant to moisture

Hard-wearing against knocks and scratches

UV-stable indoors

Chemically bonded to the steel

Doesn’t peel like paint

Maintains colour integrity

A high-quality powder coat typically lasts 20–30 years before showing wear and in low-touch areas can last significantly longer.

Zinc Coating: The Essential Upgrade for Humid Environments

Steel does not rust indoors.

However, persistent humidity (such as in bathrooms and pool areas) needs proper specification.

All our systems can be zinc-coated, including:

InoCross20

InoCrossSculpture

InoCross20FR

Sliding

Bifold

Fixed screens

Double door sets

What zinc coating does:

Forms a sacrificial shield

Stops corrosion even in steam-heavy rooms

Improves finish integrity

Counteracts water exposure

Important for indoor pools, spas and wellness suites

With the application of both zinc coating and powder coat, steel remains stable even in the most humid environments.

The Role of Welded 3D Barrel Hinges

Hinges are a majorly understated component and are one of the key factors a door does or doesn’t lasts so long.

Most companies use:

ball-bearing hinges

budget butt hinges

concealed hinges that fatigue

aluminium-compatible hinges

We use: Welded 3D barrel hinges designed to last a lifetime.

Why they outperform other hinge types:

Fully welded = zero movement at fixing points

3D adjustability ensures perfect long-term alignment

Built to support heavy steel doors

No reliance on screws (which can loosen)

Designed for long-term repeated operation

Extremely quiet and smooth

Almost maintenance-free

A steel door is only as strong as its hinge and welded barrel hinges are the highest standard in the industry.

Glass Lifespan: The Hidden Win Most Clients Don’t Consider

Internal steel doors use architectural glazing such as:

toughened glass

laminated glass

reeded glass

frosted/opaque

tinted grey or bronze

specialty laminated interlayers

These glasses do not degrade indoors.

No warping, no tint changes, no bowing, no internal moisture issues. Laminated and laminated glass can last 50–70+ years.

Many replacement projects you see online involve swapping the frame, not the glass, because the glass is usually still perfect.

Installation Quality & Tolerances

Even a perfect steel door can underperform if installed incorrectly. This is the case for every precision-made system.

Longevity relies on:

correct tolerances for hinge placement

level floors

plumb walls

proper screw fixing technique

correct sealing

correct operation testing onsite

Our survey team ensures installation longevity by checking:

floor levels

opening makeup

access conditions

wall uprights

structural surroundings

This prevents operational issues years later.

Steel vs Aluminium: Real Longevity Comparison

Aluminium deteriorates faster due to:

mechanical joints loosening

flexing under repeated use

denting

scratches showing silver base metal

powder coat breakdown

bar depth limitations

poorer tactile quality

Aluminium generally feel good for a few years, then begins to show weakness. Steel feels good forever.

Lifespan comparison:

Steel: 50+ years

Well-made aluminium:10–15 years

Cheap aluminium marketed as steel: 5–10 years

Steel vs Timber: Even More Dramatic Differences

Timber struggles with:

warping

swelling

bowing

shrinking

cracking

hinge loosening

paint peeling

Even premium hardwood doors have a typical lifespan of around 10 years under internal humidity changes.

Steel outperforms timber in every measurable way except acoustic softness and even then, accoustic laminated glass solves that.

Maintenance Requirements (Extremely Low)

Steel internal doors require minimal upkeep:

Recommended care:

occasional cleaning of powder coat

periodic glass cleaning

hinge dusting (optional)

rarely: lubrication of moving components

There is no painting, no sanding, no resealing, no realignment unless the building moves.

This is why steel is favoured in high-end residential projects; it’s a premium now and essentially free to maintain.

Longevity Myths Explained

Myth 1: Steel dents easily

Not true for welded steel. This myth comes from thin steel sheets, which are susceptible to dents.

Myth 2: Steel rusts indoors

Only if incorrectly specified and you offer zinc coating.

Myth 3: Steel is too heavy

Weight is a benefit; it creates luxurious tactility.

Myth 4: Steel is industrial-looking

Finishes, bar layouts and glass options allow any aesthetic.

Red Flags in Competitors' “Steel-Look” Doors

Cheap suppliers often present aluminium systems as steel. Red flags include:

visible screw joints

clip-in beads

lightweight feel

overly thick profiles

weld-free corners

magnet not sticking to bars

inconsistent bar depth

These products last 5–8 years on average, nothing like welded steel.

We encourage clients to use the magnet test on:

beads

bars

hinges

kickplated/metal infill panels

The frame may be steel, the rest often isn’t.

Real Examples of Longevity in Action

You’ve probably seen historic steel windows from 100 years ago still functioning beautifully.

Modern welded steel internal doors with improved coatings and fabrication? They will last at least as long.

The Real Lifespan Summary

Steel frame: 50+ years

Powder coat: 20–30 years before optional refinishing

Glass: decades (often lifetime)

Hinges: lifetime (welded 3D barrel hinges)

Hardware: 10–25 years, depending on finish

Overall: a true lifetime system

Few interior features offer a similar return on investment.

Conclusion: Steel Internal Doors Are Built for Generational Use

When properly fabricated, finished and installed, steel internal doors outlast almost every other architectural component in a modern home.

They do not warp, flex, corrode or weaken.

They require minimal maintenance.

They retain their structural stability for decades.

And with zinc coating, they excel even in humid environments.

Longevity is not a bonus feature; it is the natural behaviour of welded steel.

For clients who value permanence, refined design and architectural clarity, steel internal doors are not just a design choice; they’re a long-term investment in the home.

Ready to get your steel doors?

Enquire today to discuss your next project:

Submit an enquiry or call our team for a tailored consultation.

Let’s Talk

Whether you're renovating a home, specifying for a new build, or delivering a luxury interior for a client — we’re here to help.

At Joshua James, we work with architects, interior designers, homeowners and contractors across the UK to design and supply bespoke steel internal doors. Every door is crafted to exacting standards, tailored to suit each project’s vision, and built to stand the test of time.

If you're ready to elevate your next project with precision-made steel framed doors, let’s talk.