Steel vs Aluminium Internal Doors: What Architects Need to Know

Introduction

In high-end architecture and interior design, the finer details define the outcome. Internal doors are no longer just functional elements — they shape sightlines, influence acoustics, and contribute to the perceived quality of a space.

Steel and aluminium are two popular materials for glazed internal doors. At first glance, they may appear similar. But dig deeper, and the differences become clear — not just in how they look, but how they perform, how they’re constructed, and how they age.

In this article, we explore the key distinctions between steel and aluminium internal doors, and why steel is increasingly the first choice for architects, designers and homeowners creating sophisticated interiors.

First Impressions: Sightlines & Design Detail

Steel-framed doors are renowned for their slim sightlines, allowing larger glazed areas with minimal visual interruption. This is due to the inherent strength of steel — it supports weight without bulky reinforcement, making it ideal for internal glazing and room dividers where clean lines and open flow are key.

Aluminium, by contrast, typically relies on thicker extrusions to achieve structural strength. Even slimline aluminium systems often result in chunkier profiles, particularly around door junctions and corners. These thicker frames can disrupt the visual clarity of a design — especially in minimal, open-plan layouts.

Key Takeaway: Slimmer frames = more light, better views, and a more refined aesthetic. Steel wins.

Fabrication & Structural Stability

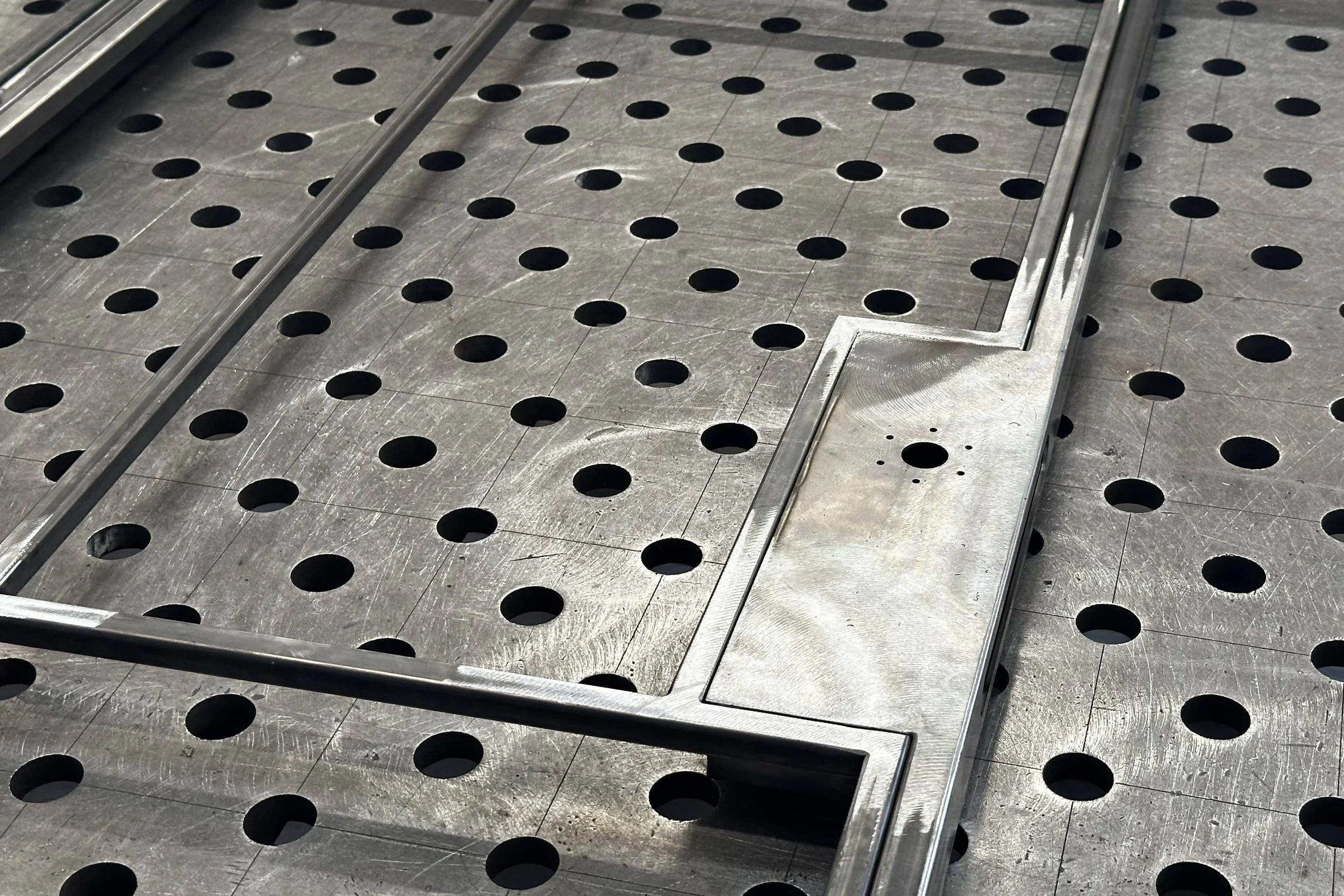

Steel doors are welded, creating a single, unified frame. There are no mechanical joints, no flexing sections, and no visible seams. This fabrication method makes steel systems exceptionally stable, even over tall or wide openings.

The unified frame that well-constructed steel doors feature comprises the outer door border, one side of the bead and bars. Welding these components not only adds additional strength and stability constructed with a seamless finish in mind.

Aluminium doors, on the other hand, are usually screw- or clip-together systems. Over time — particularly in high-use settings — these joints may loosen, resulting in creaks, misalignment, or dropped doors.

This matters not just for durability, but also for perceived quality. A door that feels loose or unstable quickly undermines a luxury design intent.

“Our doors are solid, flush and precise — the kind of detail that elevates a home’s value.”

Tactility & Operation

Clients don’t just see a door — they feel it. Steel doors deliver a weighted, deliberate operation. They open smoothly, latch quietly, and offer a reassuring resistance that communicates quality.

Thanks to the inherent strength and rigidity of steel, these doors can be configured in a wide range of formats — from classic hinged and space-saving sliding systems to bifold arrangements and entirely bespoke layouts. Steel enables design freedom without compromising stability. In contrast, aluminium systems are often limited by the strength of their extruded profiles, which restricts their application and imposes boundaries on what can realistically be achieved in both form and function.

Aluminium doors, even well-fitted ones, often feel lighter or hollow, and frequently rely on off-the-shelf components, bulky seals or gasket covers. In luxury interiors, these tactile and visual compromises are noticeable — and costly in client satisfaction.

Pro tip: Architects often bring clients into our showroom so they can physically compare door types. The feel of a steel door nearly always seals the decision.

Customisation & Finish

Steel offers complete design flexibility. At Joshua James, each steel internal door is custom-made, allowing:

Fully bespoke bar layouts (e.g. 3-bar, offset, or asymmetrical)

Precise frame dimensions

Matching fixed screens or sidelights

Custom handle placement

Finishes from classic Jet Black to metallic bronze or textured neutrals

Aluminium systems often come as modular kits, limited to predefined profiles. You may be able to alter frame height and glass, but bar layouts, handle positions and edge detailing are generally fixed.

Steel doors are crafted to your specification — not adapted from a base model.

Long-Term Performance & Value

While aluminium doors may be more affordable upfront, steel offers far greater longevity and minimal ongoing maintenance. A properly fabricated and installed steel door can last decades without sagging, warping, or needing adjustment.

Aluminium frames are more susceptible to wear, especially around hinges and pivot points. Internal rubber seals or caps may perish over time, affecting both appearance and performance.

For clients building homes to last — or those investing in premium refurbishments — steel doors are a smart, future-proof choice.

Acoustic Considerations

In internal applications, acoustic performance is often a bigger concern than thermal insulation. Steel systems, when glazed with acoustic or laminated glass, provide excellent sound separation between rooms — ideal for:

Home offices

Bedrooms

Snugs and cinema rooms

Dressing rooms

Pool or spa zones

Aluminium can offer good acoustic performance too, but often requires added seals and bulkier frames, which compromise the visual appeal.

Applications in Luxury Interiors

We commonly produce steel doors for:

Room dividers in open-plan layouts

Full-height hinged or pivot doors with clean vertical sightlines

Sliding systems between kitchen/dining areas and entertainment spaces

Glazed home offices that require privacy but still feel open

Fire-rated partitions that preserve light and elegance

Steel doors offer a timeless aesthetic — equally at home in Georgian townhouses, modernist villas, converted barns, or penthouse apartments.

Sustainability & Materials

Steel is highly recyclable and often fabricated using reclaimed material. Because steel doors last significantly longer than most aluminium equivalents, they contribute to a more sustainable built environment — reducing waste and replacement cycles.

Aluminium is also recyclable, but many aluminium door systems have a shorter service life, particularly when exposed to mechanical wear, making steel the more responsible long-term choice in many projects.

What Architects & Designers Should Consider

When specifying internal doors for a high-end project, it’s essential to look beyond surface aesthetics. Consider how the door will perform over time, how it integrates with the surrounding architecture, and whether the system can be tailored to suit the exact requirements of the space. Architects and designers working in the premium residential sector often prioritise materials that offer both longevity and design flexibility — and steel consistently delivers on both fronts. From precision-welded construction to fully bespoke layouts and refined finishes, steel internal doors provide the creative freedom and technical reliability that discerning clients expect.

Steel vs Aluminium Internal Doors specification checklist:

| Consideration | Steel | Aluminium |

|---|---|---|

| Slim sightlines | Excellent | Often thicker |

| Welded fabrication | Yes | No (mechanical fixings) |

| Fully bespoke design | Yes | Limited |

| Long-term stability | Excellent | Prone to drop/warp |

| Tactile quality | Solid & smooth | Lighter feel |

| Sustainability | Long lifespan & recyclable | Recylable but shorter lifespan |

Conclusion

Steel and aluminium internal doors may look similar at first glance — but in terms of longevity, design control, structural integrity, and tactile quality, steel stands apart.

Beyond performance and longevity, specifying steel internal doors also reflects a broader design philosophy — one that values craftsmanship, precision, and permanence. These aren’t off-the-shelf systems. They’re architectural features that elevate the everyday experience of a space. For clients investing in high-end homes or bespoke renovations, steel offers a level of detail and refinement that aluminium simply can’t replicate.

If you're delivering a luxury home or a standout interior, your doors should reflect the same design intent as your flooring, lighting or bespoke joinery. They should last. They should feel solid. They should look effortless.

At Joshua James, we create bespoke, made-to-order steel doors that meet these expectations. We work with architects and designers across the UK, offering a full design-to-delivery service — with short lead times and flawless results.

Ready to specify steel?

Enquire today to discuss your next project:

Submit an enquiry or call our team for a tailored consultation.

Let’s Talk

Whether you're renovating a home, specifying for a new build, or delivering a luxury interior for a client — we’re here to help.

At Joshua James, we work with architects, interior designers, homeowners and contractors across the UK to design and supply bespoke steel internal doors. Every door is crafted to exacting standards, tailored to suit each project’s vision, and built to stand the test of time.

If you're ready to elevate your next project with precision-made steel framed doors, let’s talk.